- Contract Manufacturing

- Custom manufacturing

- Plastics & Polymer Technology

Forming Processes

Composite Materials

- Machining

Specialized Machining

- Sheet Metal Technology

Forming Processes

Bending Processes

Specialized Techniques

Cutting Processes

- Fabrication technology

Welding Technologies

Joining Processes

specialized welding Technologies

Plastic Joining Technologies

- Metal casting

Traditional Casting Methods

Specialized Casting Techniques

Modern Casting Processes

- Finishing Techniques

Coating Processes

Other Processes

Surface Treatments

Printing Techniques

- Engineering

Product Development

Material Development

Metrology & Support

- Additive Manufacturing

ADDITIVE MANUFACTURING

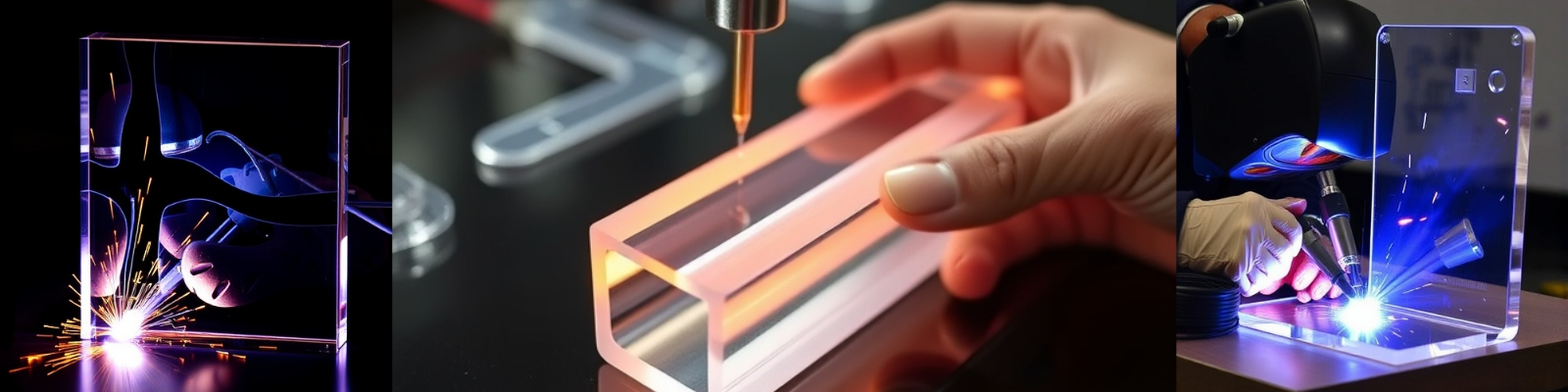

At Nexams, we specialize in providing high-quality Acrylic Welding services to meet the diverse needs of our clients. With a focus on precision and durability, our acrylic welding solutions ensure that your projects achieve the highest standards of quality and performance.

What is Acrylic Welding?

Acrylic Welding is a process used to join acrylic (PMMA) materials through various welding techniques. This process can involve the use of adhesives, solvent welding, or thermal welding methods to create strong, transparent joints that maintain the aesthetic qualities of acrylic. Acrylic welding is widely utilized in various industries due to its versatility and ability to produce durable, clear joints.

How we can Support your Manufacturing needs

Our expert technicians utilize advanced ultrasonic welding technology to deliver precise and consistent welds, ensuring strong connections for various applications.

We collaborate closely with clients to develop tailored ultrasonic welding solutions that address specific project requirements, from prototyping to large-scale production.

At Nexams, we implement rigorous quality control measures throughout the welding process, guaranteeing that every joint meets industry standards and customer expectations.

Medical Equipment

Roto molding is utilized to manufacture medical devices and storage solutions that require both durability and compliance with stringent hygiene standards. Products such as medical storage bins and equipment housings are designed to withstand rigorous use in healthcare environments.

Agricultural Products

This process efficiently produces durable items for agricultural applications, including fertilizer tanks, watering containers, and feed bins. These products are specifically engineered to endure harsh outdoor conditions while maintaining their structural integrity.

HVAC Components

Rotational molding is ideal for creating components used in heating, ventilation, and air conditioning (HVAC) systems, such as ducts and housings. The lightweight yet sturdy parts produced enhance overall system efficiency and performance.

Sports Equipment

A variety of sports equipment is manufactured using roto molding, including kayaks, helmets, and protective gear. The flexibility in design combined with material strength ensures that these products meet the rigorous demands of various sports activities.

Handheld Ultrasonic Welding:

Portable units used for smaller, more intricate welds, allowing flexibility in various settings.

Automated Ultrasonic Welding:

Fully automated systems designed for high-volume production, providing consistency and efficiency.

Rotary Ultrasonic Welding:

Used for continuous production processes, particularly in packaging and textiles, ensuring fast and efficient welding.

Speed and Efficiency:

The rapid welding process significantly reduces cycle times, increasing overall production efficiency.

Strong, Durable Joints:

Produces high-quality welds without the need for adhesives, ensuring clean and reliable connections.

Minimal Heat Affected Zone:

Localized heating minimizes damage to surrounding areas, preserving the integrity of the materials.

Environmentally Friendly:

Eliminates the need for solvents and adhesives, making it a sustainable option for joining plastics.

Versatility:

Capable of welding a wide range of thermoplastic materials, making it suitable for various applications and industries.

Automation Compatibility:

Easily integrated into automated production lines, enhancing manufacturing efficiency.

Automotive:

Interior Components: Joining dashboards, door panels, and trim pieces for enhanced durability and aesthetics.

Fuel Tanks: Creating leak-proof joints in fuel tanks and reservoirs, essential for vehicle safety.

Medical Devices:

Single-Use Products: Manufacturing sterile and reliable disposable devices like syringes, IV bags, and surgical tools.

Complex Assemblies: Assembling intricate medical devices with precision to ensure functionality and safety.

Consumer Electronics:

Housings: Welding plastic enclosures for devices such as smartphones, tablets, and laptops, ensuring strong, lightweight, and aesthetically pleasing products.

Internal Components: Joining parts within electronic devices to enhance durability and performance.

Packaging:

Sealed Containers: Creating airtight seals in packaging, which is crucial for preserving product freshness and integrity.

Blister Packs: Commonly used in pharmaceuticals and consumer goods to ensure safe and hygienic packaging.

Textiles and Non-Wovens:

Fabric Joining: Welding non-woven fabrics for products like disposable diapers and medical gowns, ensuring strong and hygienic connections.

Cut and Seal: Efficiently cutting and sealing fabrics in a single process, reducing production time.

Industrial Applications:

Component Assembly: Joining plastic components in machinery and equipment for reliable and durable performance.

Custom Parts: Manufacturing custom plastic parts and assemblies to meet diverse industrial needs.

How It's Manufactured

Get Into Touch

Whether through a call or email, we’re here to help.