Scroll to discover the technology behind precision.

From concept to final component, we handle every step of your manufacturing process.

So you can focus on innovation while we take care of execution.

Scroll to discover the technology behind precision.

From concept to final component, we handle every step of your manufacturing process.

So you can focus on innovation while we take care of execution.

Nexams Manufacturing Company is a forward-thinking industrial manufacturer dedicated to delivering high-quality, precision-engineered components and custom manufacturing solutions for a wide range of industries. With a strong foundation in innovation, engineering reliability, and customer satisfaction, Nexams has earned a reputation as a trusted manufacturing partner across the globe.

Founded with the vision to bridge the gap between advanced manufacturing technology and practical application, Nexams specializes in the design and production of custom-engineered parts, industrial machinery, and high-performance equipment manufacturing. Our solutions are tailored to meet the evolving needs of industries including automotive, aerospace, electronics, and heavy engineering.

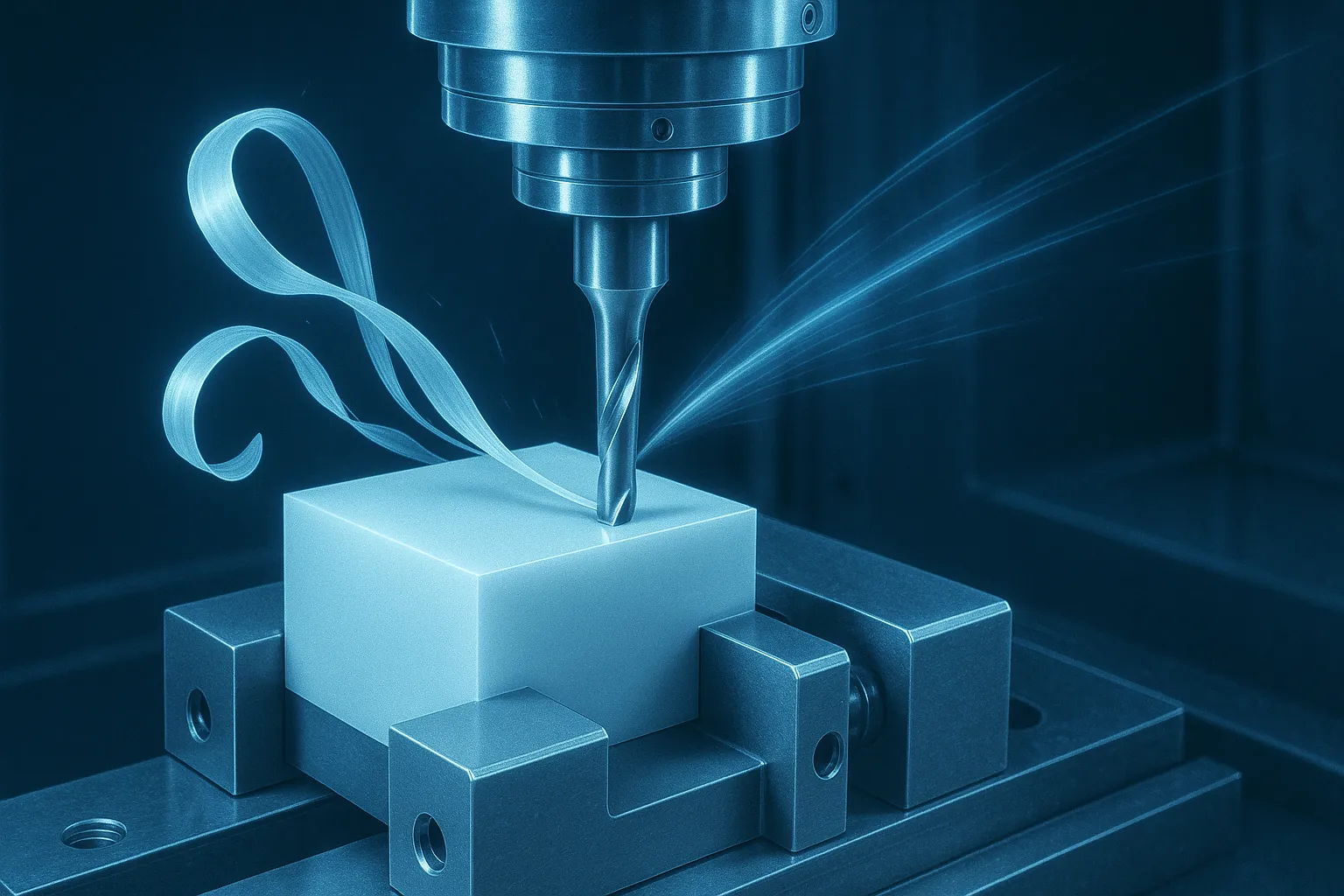

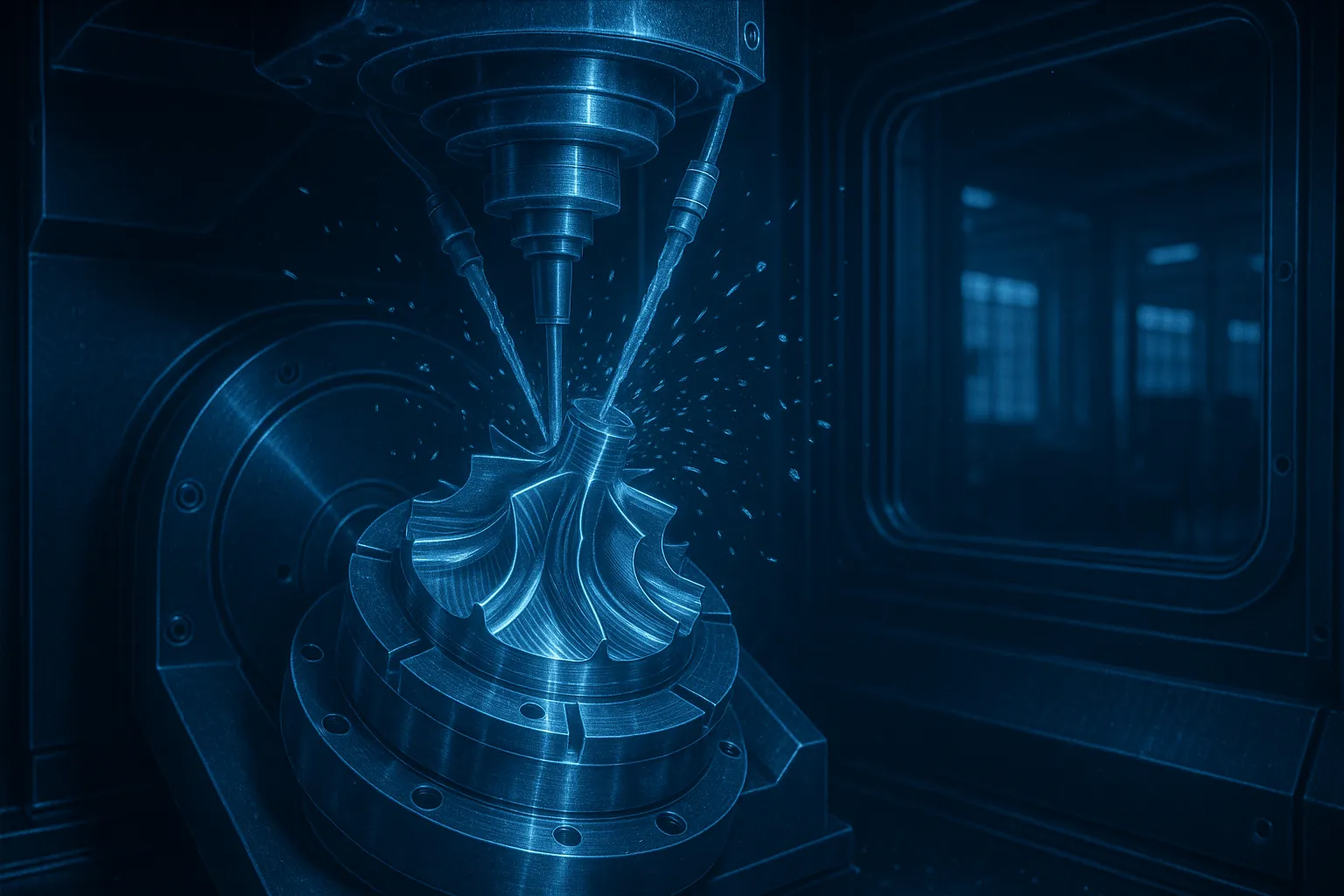

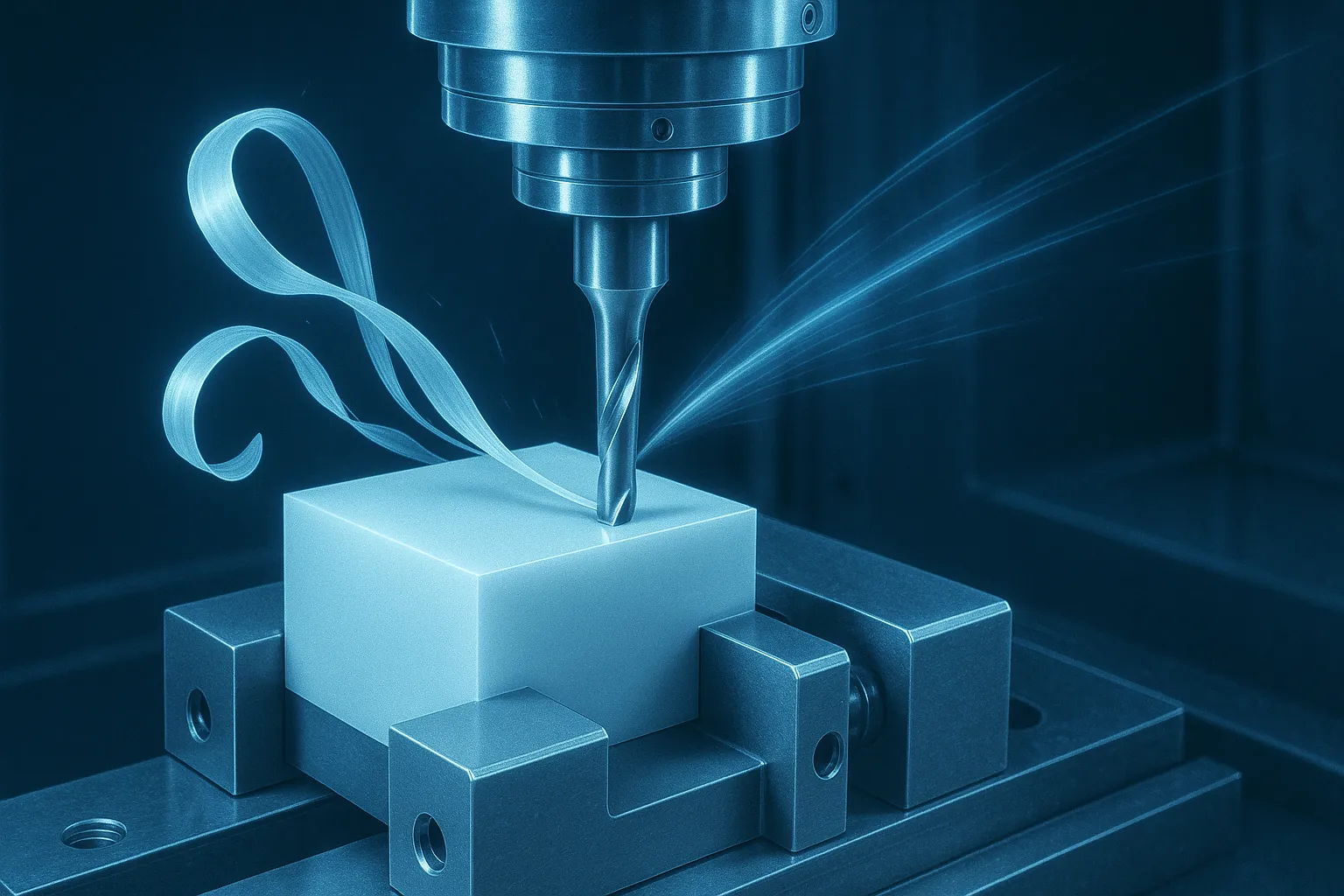

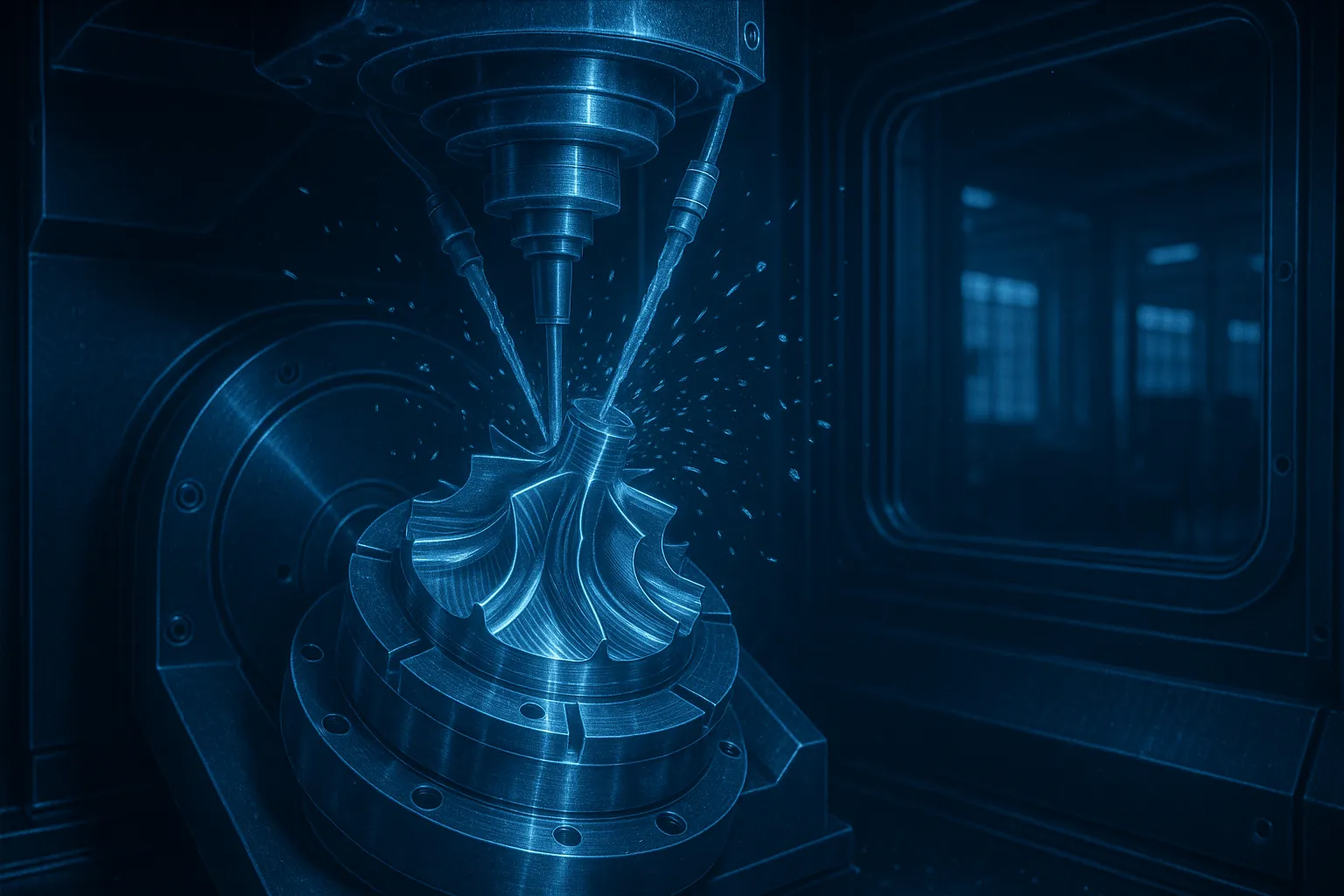

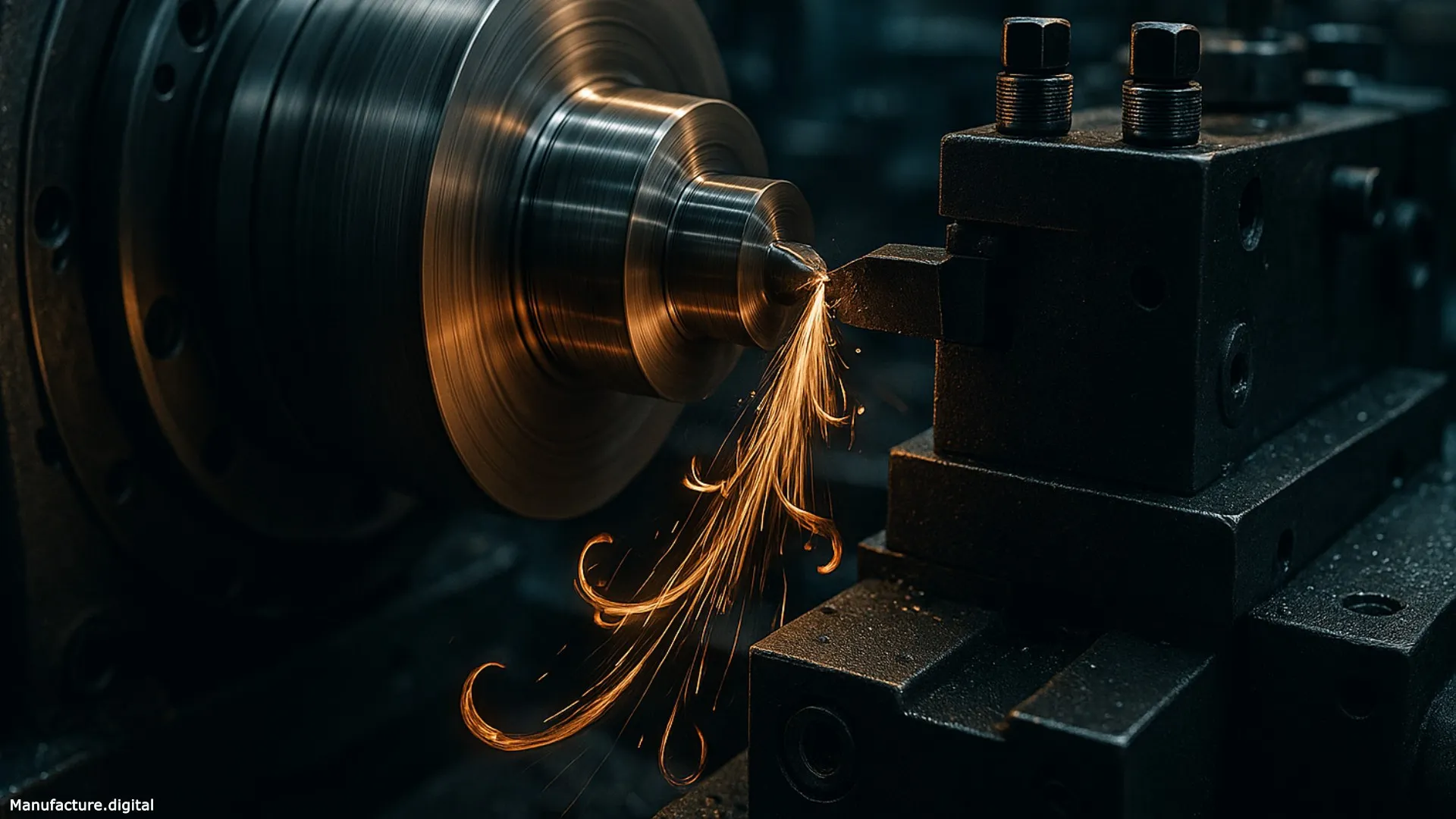

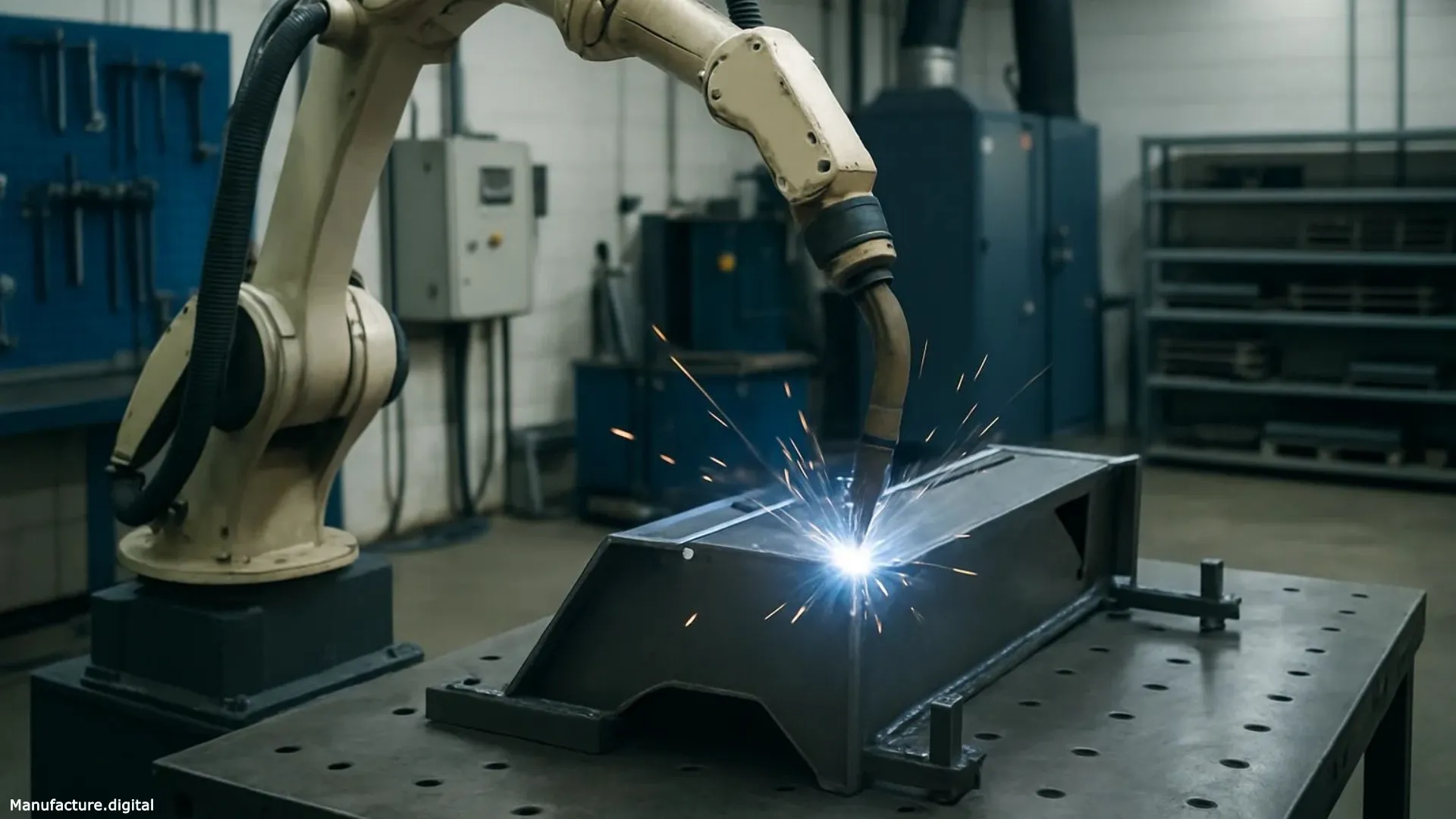

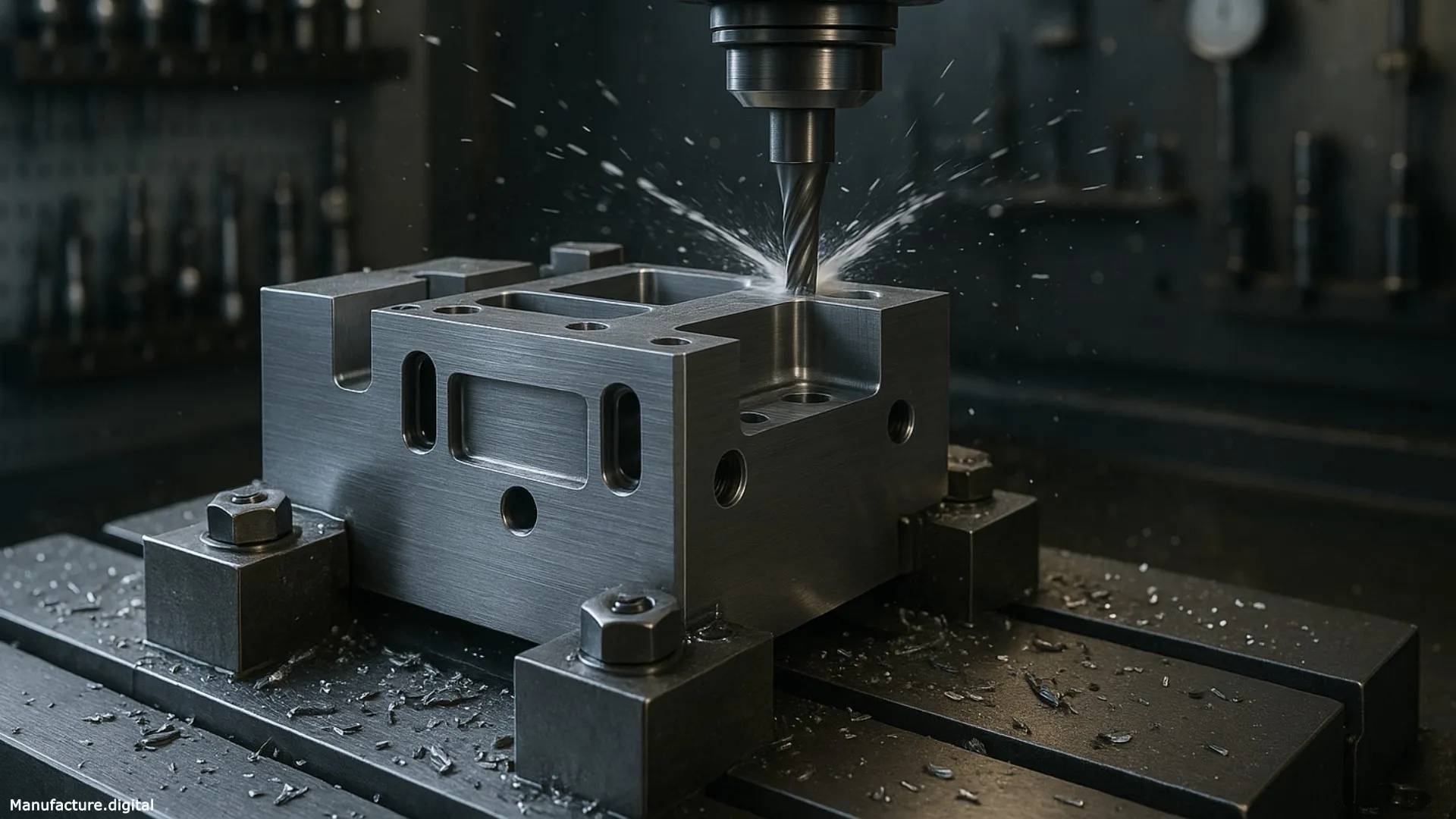

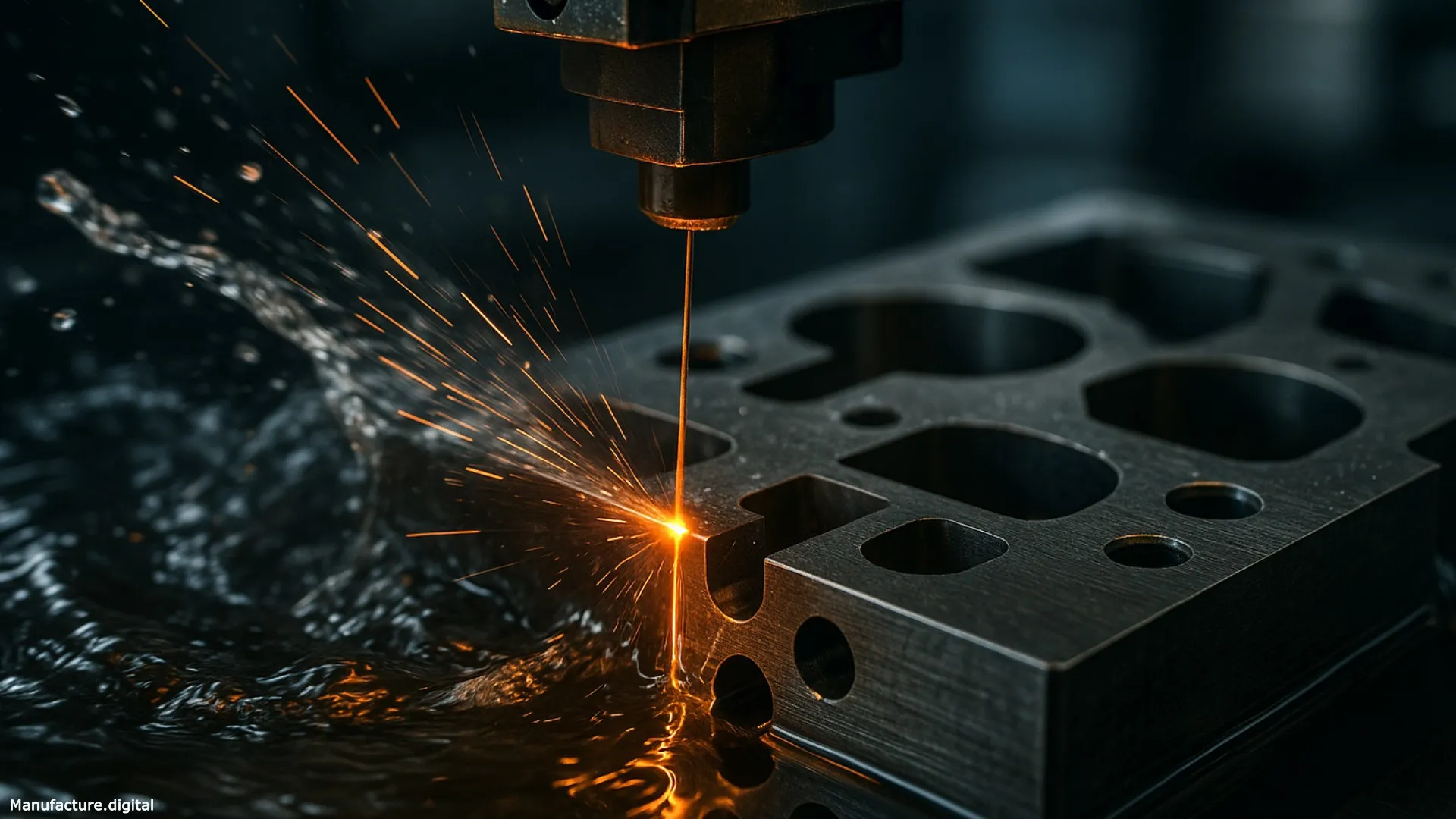

Our state-of-the-art manufacturing facilities, equipped with modern CNC machines, automation systems, and quality control technologies, are supported by a highly skilled workforce. This enables us to uphold strict quality standards, ensure on-time project delivery, and consistently exceed customer expectations.

From concept to completion, we work collaboratively with clients to transform their ideas into precision-manufactured components and systems that drive efficiency, scalability, and performance.

At Nexams, excellence is not just a standard it’s a mindset. Whether you're looking for precision manufacturing, custom part production, or end-to-end supply chain support, Nexams is your trusted partner in achieving industrial success and manufacturing efficiency.

We invest heavily in research & development to ensure that every product we manufacture incorporates the latest advancements in materials, technology, and design efficiency.

With streamlined production workflows and agile systems, We deliver faster than the industry average without cutting corners on precision or durability.

Clients get full visibility into their production status with real-time updates, milestone tracking, and transparency from concept to delivery.

We build lasting relationships. Our clients stay with us not just because of quality — but because of trust, responsiveness, and shared growth.

We begin with a collaborative discovery session to fully understand your product goals, technical requirements, timeline, and industry standards. Whether it’s a custom part or full assembly, we align with your vision from day one.

Our engineering team develops detailed 2D/3D models and manufacturing blueprints using CAD and simulation tools. We optimize for precision, durability, and manufacturability before moving into prototyping.

Before full-scale production, we create prototypes or pilot runs for testing and approval. This ensures the design meets both functional and performance benchmarks with minimal risk.

Once approved, production begins in our ISO-compliant, tech-enabled facility. Every unit passes through rigorous quality checks using automated inspection systems to ensure 100% accuracy.

We handle safe packaging, on-time delivery, and post-shipment technical support. Our team remains accessible for future orders, adjustments, or scaling up your production needs.

From prototyping to production, our facility is equipped for CNC machining, molding, casting, forming, welding, finishing, and inspection eliminating delays and reducing costs.

Our team combines engineering knowledge with advanced machinery to deliver high-precision components tailored to your specifications from the simplest part to the most complex assembly.

Whether it’s a single prototype or a large volume batch, we deliver with speed, consistency, and quality thanks to our lean workflows, skilled team, and robust quality control systems.

Get quick technical insights effortlessly!

Whether through a call or email, we’re here to help.